Dust remains one of the biggest challenges on a mine site.

It impairs visibility, wears out machinery and affects workers’ health.

To remedy this, most sites still use continuous watering or chlorinated salts (CaCl₂, MgCl₂).

Expensive, short-lived and often harmful to the environment.

This article aims to explain the principles and potential of biocimentation for dust control, based on existing literature. It does not yet present any in-house experiments.

Why watering and chlorinated salts are no longer enough

Watering wastes resources

Spraying water every day sounds simple, but it’s a false solution.

In warm climates, water evaporates within a few hours.

It’s better to stabilize a mining track to reduce watering.

On some mining slopes, daily water consumption can reach several thousand liters, depending on climate and watering frequency (estimate based on field observations).

A heavy logistical and economic burden for isolated sites.

Chlorinated salts: useful but problematic when overused

Chlorinated salts, such as calcium chloride (CaCl₂) or magnesium chloride (MgCl₂), are often used on mine slopes to keep a little moisture and limit dust for a while.

When properly dosed, they can even provide useful calcium for certain biocimentation processes.

The problem is when you use too much, too often.

Here, the effects quickly become negative: vehicles and metal structures corrode, soils and run-off water become contaminated, and there is a risk of non-compliance with environmental standards (ISO 14001).

Hence the need to use them with care: in a sustainable approach, they must remain a simple reagent, not the heart of the solution.

Short-lived effectiveness

In many operational cases, the effectiveness of chlorinated salts for dust reduction diminishes within a few days if conditions are unfavorable (high traffic, poorly treated soil, rain or runoff).

Chemical solutions such as calcium or magnesium chlorides have shown immediate effectiveness (Shaikh et al., 2023), but their action is short-lived and their environmental impact remains problematic.

This means frequent reapplication, which increases fuel costs, etc.

Bio-sourced binders therefore show great potential for stabilizing the edges of runways, storage areas and non-road surfaces, where mechanical loads are moderate.

Their application on the main taxiways will be the subject of further tests.

Inconsistency with HSE and CSR objectives

These products no longer fit in with the sustainability policies of the major mining groups.

Several European and Australian countries now restrict their use.

Example:

A gold mine in Western Australia was consuming 15,000 L/day for watering.

Within three months, corrosion of the equipment led to an 8% increase in maintenance costs.

The site then looked for a non-toxic, less water-intensive solution.

How bio-sourced mineral binder works (MICP)

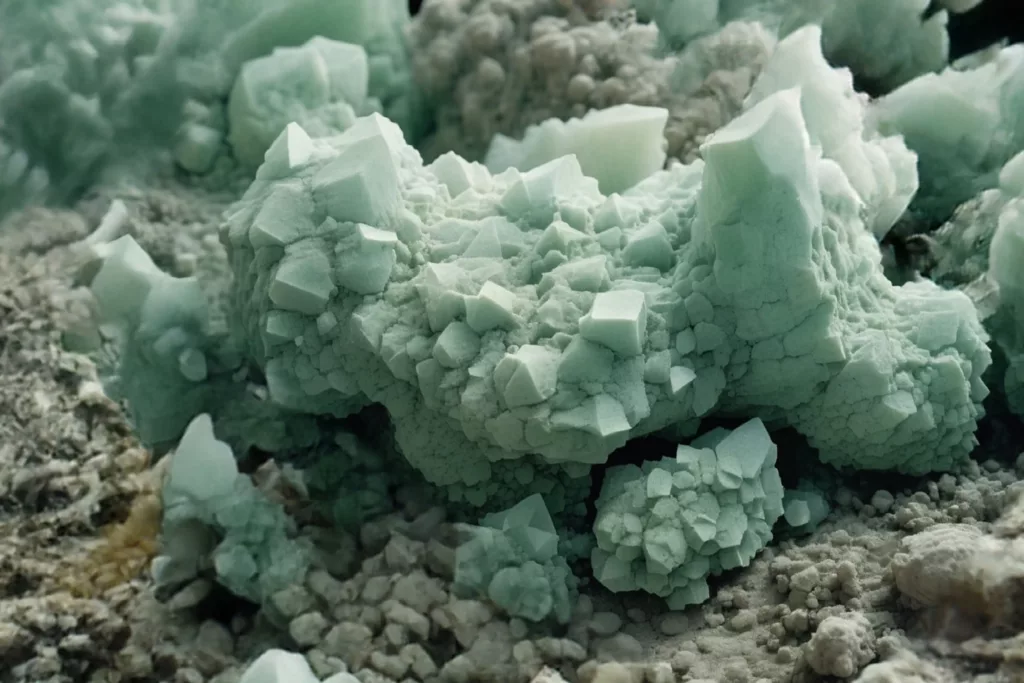

Bio-sourced mineral binders are based on a natural process known as biomineralization(MICP).

This reaction forms calcium carbonate (CaCO₃), which acts as a mineral glue, fixing the fine particles together and stabilizing the surface.

Recent studies have demonstrated the effectiveness of MICP in open-pit mining.

Mechanism

- Application of a neutral liquid containing calcium ions.

- Bacteria activate a natural reaction that precipitates CaCO₃.

- This carbonate crystallizes between the grains, forming a mineralized crust resistant to wind and vehicle traffic.

Why it’s safer and more efficient

- Toxicity-free: pH neutral (≈ 7-8), ammonium- and chloride-free.

- Zero corrosion: compatible with steel and metals.

- Less water: up to 80% water savings (estimated).

- Long-lasting: efficacy from 1 to 3 months before reactivation (estimated).

- Easy to apply: works with existing tanker trucks.

Caution: Effectiveness can be maintained for several weeks on lightly trafficked areas. On the other hand, for main tracks, a more frequent treatment may be necessary.

Application method

- Surface preparation: cleaning and levelling.

- Spray evenly.

- Allow the surface to dry, depending on weather conditions (generally a few hours to a day).

- Check surface cohesion after curing.

Quality control (QA/QC) :

- Visually check surface cohesion and absence of dust after passage of a light vehicle.

These steps are integrated into environmental management systems (EN ISO 14001).

Field observations and literature data

Independent studies on biomineralization show its great potential for stabilizing runway edges, deposition areas or non-running surfaces, where mechanical stresses remain moderate.

Medusoil plans to evaluate this approach directly on site in pilot trials to confirm these observations.

| Indicator | Reference (water + chlorides) | Bio-sourced binder | Deviation | Source |

| Water consumption | 20,000 L/day | 4,000 L/day | -80 % | Internal estimate |

| Visible dust | 100 % | 15 à 25 % | – 75 à 85 % | Pilot observation |

| Application frequency | 2 to 5 days | 1 to 3 months | x 15 | Internal estimate |

| Corrosion cases | Frequent | None reported | 0 | Feedback from the field |

*The values presented are indicative and will have to be validated by field tests.

Suggested test plan :

- Scope: 500 m section of mining track.

- Indicators (KPI): dust (mg/m³), water used (L/day), durability (months).

- Duration: 12 weeks.

- Method: before/after measurements (particle monitoring, ISO 4225 standard).

FAQ

How long does the treatment last?

Between 1 and 3 months, depending on climate and traffic. A light retreatment is then all that is required to reactivate the surface (excluding main runways, which require further study).

Is the product safe for operators and equipment?

Yes, it’s non-toxic, non-corrosive and pH-neutral. No release of dangerous gases or salts.

Can it be applied to existing trucks?

Yes, with the same booms and nozzles for even coverage.

Does it work in extreme climates?

Yes, but curing is slower below 10°C and faster above 30°C. Avoid application in heavy rain or wind.

Need advice for your website?

Let’s talk about your site, your constraints and your objectives. Response within 72 hours.

Contact usOr write to us at info@medusoil.com